Previous

Next

HOGI Latest Tech CNC Pump-controlled servo bending machines

- ESVP (Electro-hydrostatic Pump Unit) series servo pump control bending machine control unit, after a long period of continuous exploration and practice, for the cnc bending machine industry to develop servo motor and two-way internal gear pump combination of control of the bending machine servo pump control system, the use of servo motors and two-way internal gear pumps are connected to the servo motor through the numerical control system to control the servo motor’s speed to accurately control the output of the pump flow of hydraulic fluid, the control of bending machine synchronisation of the two cylinders, to achieve the slider position of the precise control of the speed of downward movement faster, more efficient, simple installation, energy saving and environmental protection.

Product Description

Specification

Video

Product Description

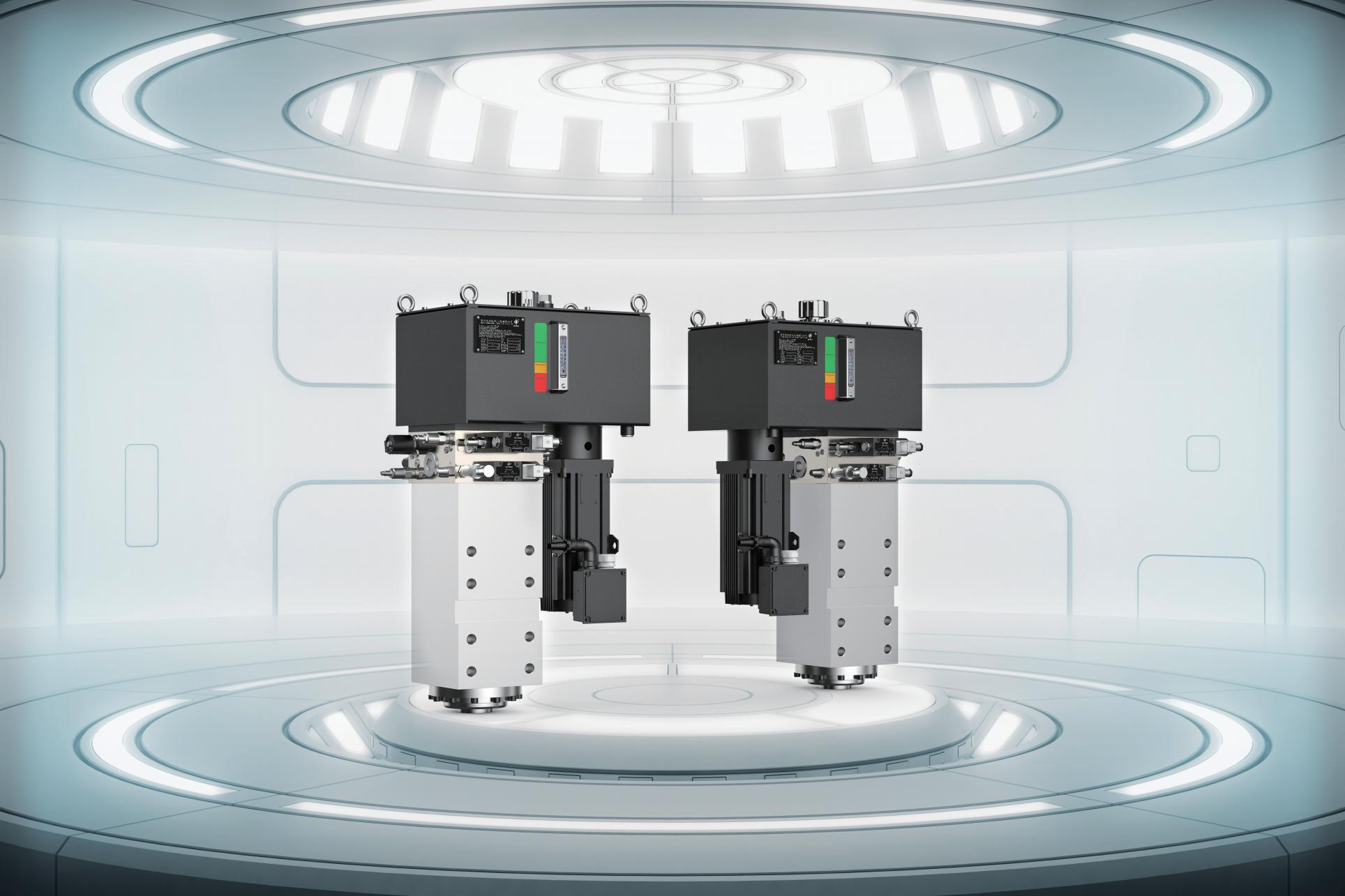

HOGI Dual Servo Pump Control Hydraulic System

for CNC Bending Machines ESVP Series

HOGI Pump-controlled servo CNC bending machines

Single-cylinder high-speed Pump-controlled CNC Press brake bending machines

ESVP (Electro-hydrostatic Pump Unit) series servo pump control bending machine control unit, after a long period of continuous exploration and practice, for the cnc bending machine industry to develop servo motor and two-way internal gear pump combination of control of the bending machine servo pump control system, the use of servo motors and two-way internal gear pumps are connected to the servo motor through the numerical control system to control the servo motor’s speed to accurately control the output of the pump flow of hydraulic fluid, the control of bending machine synchronisation of the two cylinders, to achieve the slider position of the precise control of the speed of downward movement faster, more efficient, simple installation, energy saving and environmental protection.

Features:

Fast speed.

Fast down 0~400 can be adjusted at any speed

Slow down 0~30 can be adjusted at any speed

Return 0~400 can be adjusted at any speed

Strong anti -load capacity

The oil cylinder adopts the most scientific and technological sub -tank structure, which is decreased from the decrease of the traditional bending machine by the skateboard to the hydraulic thrust, so that it will not cause the speed unstable due to changes in the skateboarding rail friction.

The guide rail consists of two 45 large linear guide rails+6 extended slider, which can ensure that the upper mold always maintains the stable movement of the line.

Specification

Video

10+Years Experience of Sheet metal processing production line automation solution

Copyright 2023 © All rights Reserved. Design by Beboss