HOGI Hybrid oil-electric CNC bending machines

Differences to conventional bending machines.

Fast: 10% increase in performance through reduced cycle times

Efficient: 50% more energy efficiency

Precise: positioning accuracy of 0.005 mm

Reliable: minimal risk of leakage

Low noise: reduced noise in all operating modes

Compact: new space created in the middle plane

Compatible: easy integration into CNS

Optimised: less installation and service costs

Environmentally friendly: significantly reduced hydraulic oil consumption

HOGI Hybrid oil-electric CNC bending machines

Differences to Traditional bending machine.

Nowdays,More and more customers go to electric hydraulic press brake because it has many advanges like below :

No 1, Top components list with world class:

1, Main motor: Siemens

2, Servo proportional valve: Hawe,Germany (for press brake, the main problems is hydraulics, the valves and pump is the center, so this can bring less hydraulic problems . )

3, Electrics:SCHNEIDER and Controller: DELEM , ESA, CYBLEC Controller, the more expensive controller, the bigger screen, programming simulation, bending angle and positioning accuracy control.

4, Sealing:NOK, Japan

5,Tools:42CrMo , All heating treatment.

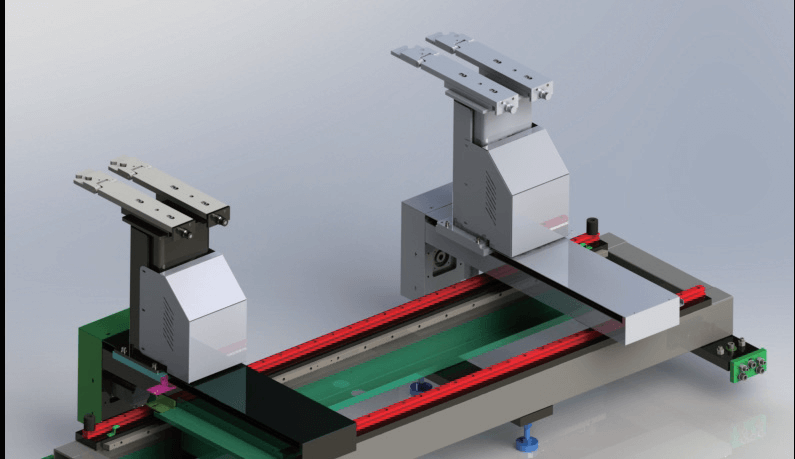

6, Taiwan Hiwin ball screw, guide linear and so on.

7, the crowning table as standard to get the best bending straightness in the bending .

8, more axis control, can save bending time for different kinds workpieces.

Fast: 10% increase in performance through reduced cycle times

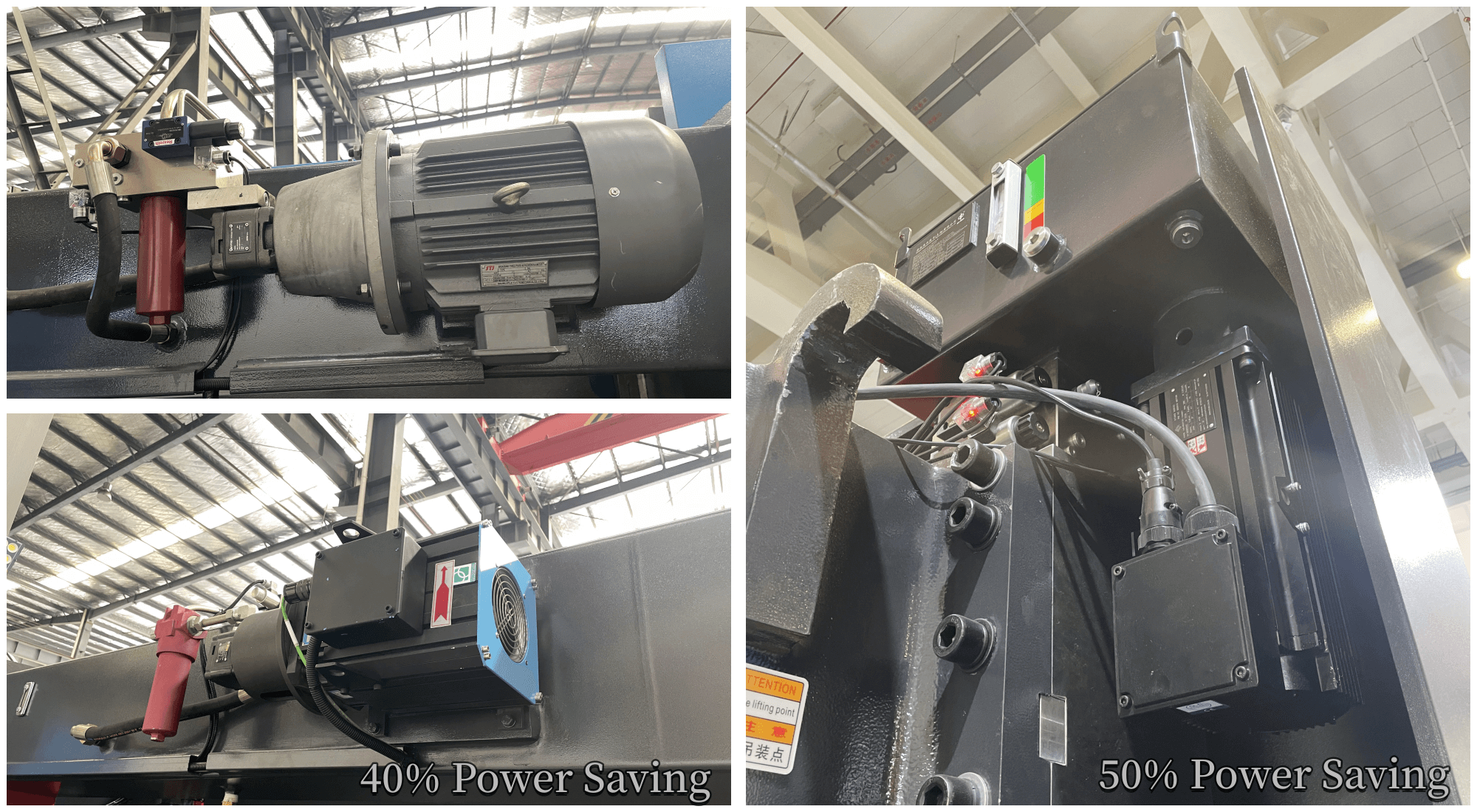

Efficient: 50% more energy efficiency

Precise: positioning accuracy of 0.005 mm

Reliable: minimal risk of leakage

Low noise: reduced noise in all operating modes

Compact: new space created in the middle plane

Compatible: easy integration into CNS

Optimised: less installation and service costs

Environmentally friendly: significantly reduced hydraulic oil consumption

New series of hybrid oil/electric bending machines

New generation of highly rigid frames

Efficient and reliable rear positioning system

Expanded processing range

Energy efficient and environmentally friendly Green bending

Finite element mechanical analysis of individual parts such as the slider, lower table and left and right columns.

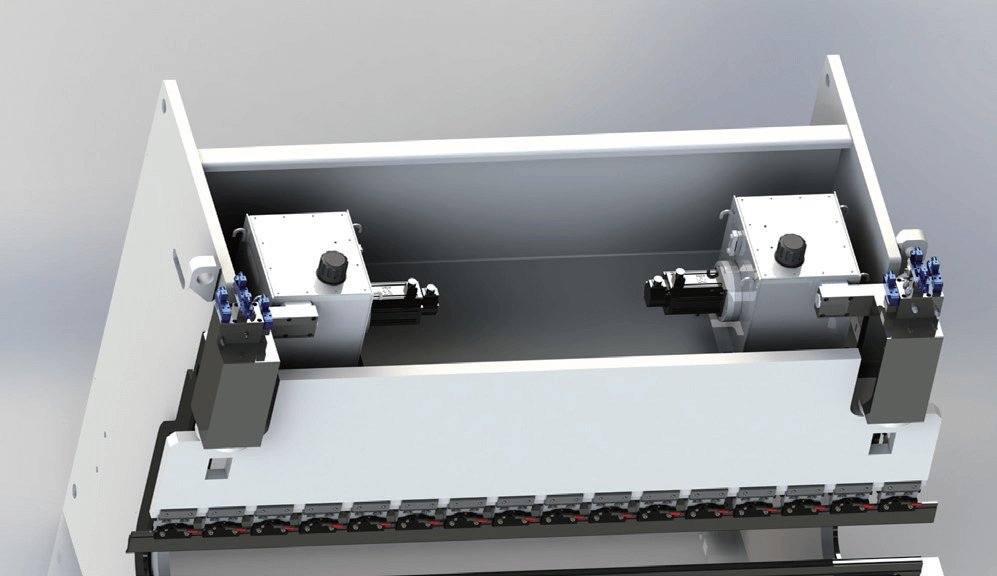

Dual servo oil-electric hybrid technology

Dual-servo oil-electric hybrid system (applicable to our oil-electric hybrid CNC bending machine), through a set of servo motors and servo pumps on the left and right, controls the fast down, bending and return actions of Y1 and Y2, and the action is fast and stable , The response speed greatly surpasses the proportional valve control, and the system has the characteristics of low noise and high efficiency.

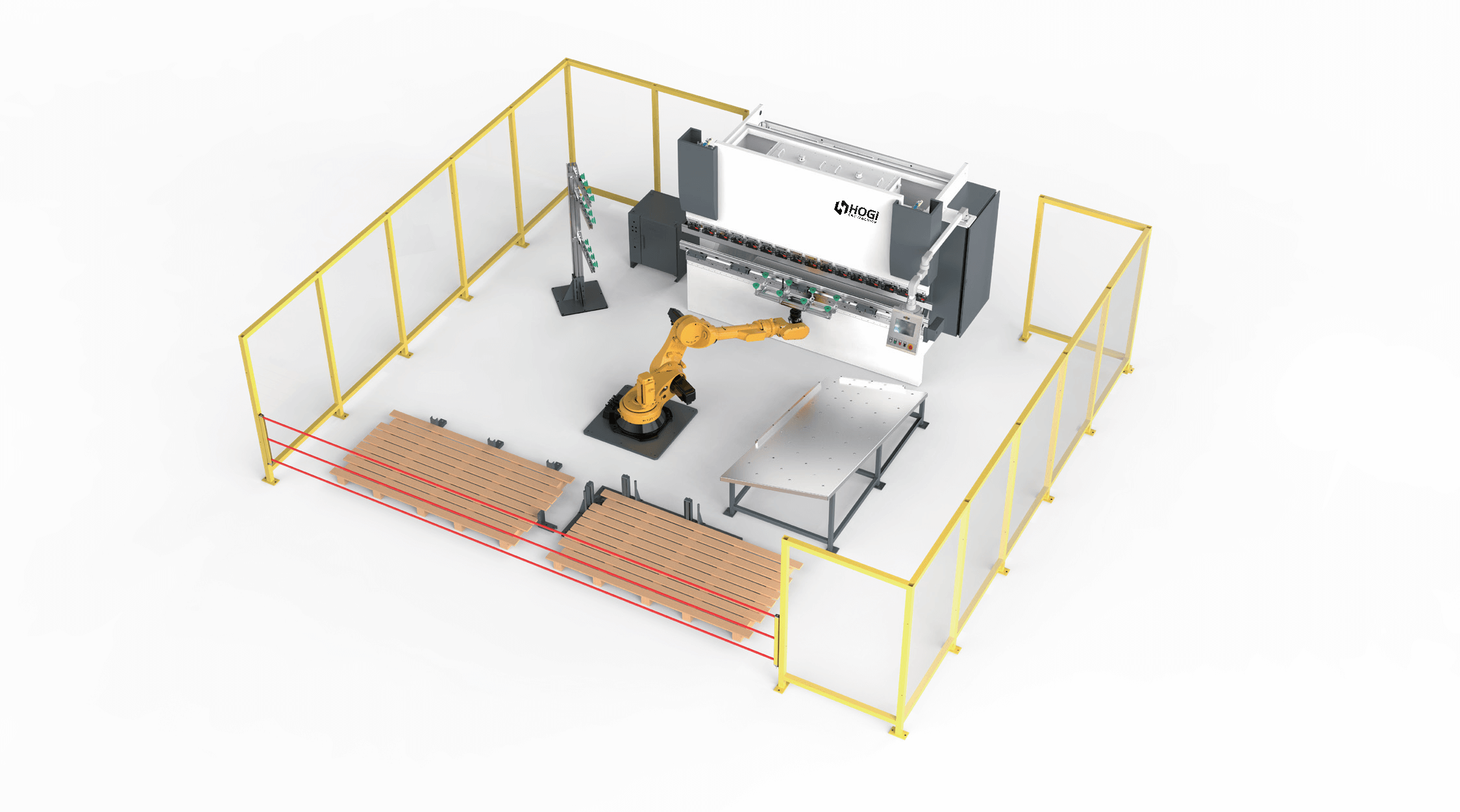

Automated robotic bending solutions

The robot bending machine unit is coordinated through multi -joint industrial robots and CNC bending machines to achieve automatic grabbing of the board. According to the weight, size and bending process of the workpiece, choose the model of bending machines and robots, and design related auxiliary devices to meet the customized needs.

Copyright 2023 © All rights Reserved. Design by Beboss