HOGI CNC hydraulic press brake

Fashionable appearance design, high rigidity, high speed electro-hydraulic synchronized CNC sheet metal bending machine.

Electro-hydraulic full servo system, with grating scale for precise positioning, realizing full closed-loop control.

Hydraulic or mechanical deflection compensation of the working table ensures workpiece processing precision.

Rear stopper is driven by servo motor, ball screw drive, linear guide rail guiding to ensure positioning accuracy.

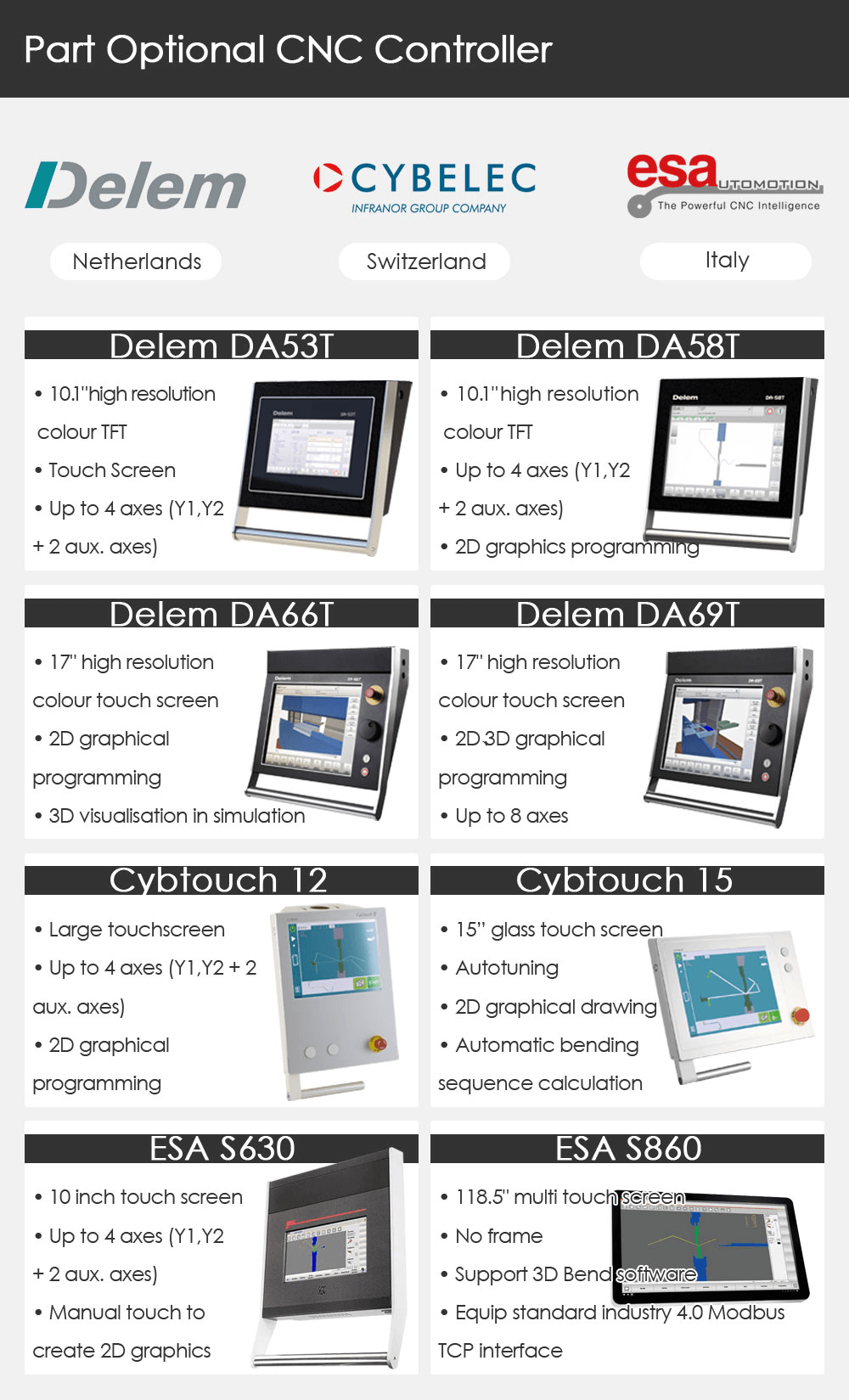

From the most common DA-52S to the upgraded DA-69T system, the brand DELEM from Holland has become the most commonly used and high quality system for hydraulic press brakes, among which DA-52S, DA-53T, DA-58T, DA-66T and DA-69T have become the main systems for our electro-hydraulic press brakes because of their easy operation and powerful functions.

HOGI CNC Hydraulic press brake bending machines

Electro-hydraulic servo synchronous CNC bending machine is installed in the slider and the body of the optical (magnetic) scale, bending machine CNC system can analyze the synchronization of the two sides of the slider through the optical (magnetic) scale real-time feedback information. If there is an error, the CNC system will be adjusted through the proportional valve to promote the synchronization of the two sides of the slider travel. CNC control system, hydraulic control valve set, scale together constitute the feedback closed-loop control of electro-hydraulic synchronous bending machine.

- Adopting new rigid design and finite element optimization analysis, it has good rigidity and stability.

- The frame is machined and formed by precision floor boring machine or multi-surface machining center at one time, which ensures the parallelism and perpendicularity of each mounting surface;

- The use of Germany Rexroth imported full closed-loop electro-hydraulic servo synchronous control system, feedback synchronization.

- speed: electro-hydraulic servo synchronous bending machine through the computer to set each bending process and save, you can continuous uninterrupted operation, effectively improve the speed of bending steps, thereby improving efficiency. At the same time when the slider goes down, the speed has a fast down and slow down function, fast and slow conversion smoothly, which can greatly improve production efficiency.

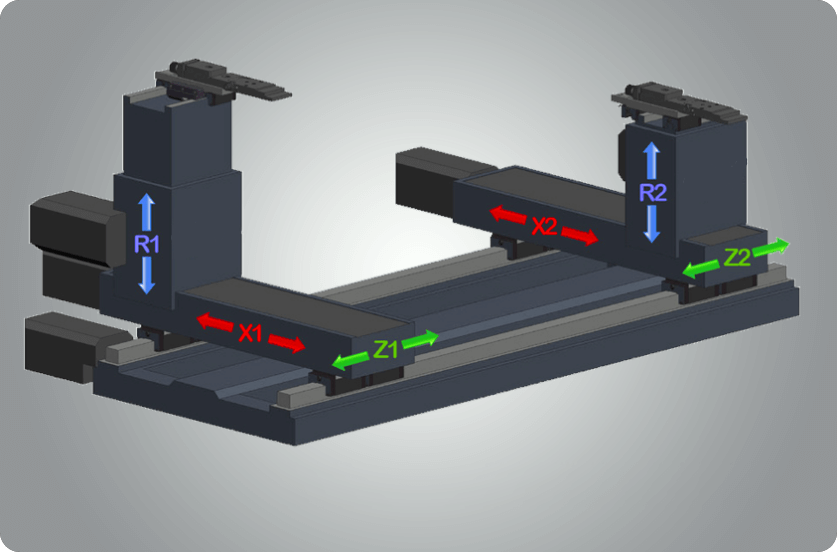

Bending machine CNC axes, the functions defined by each axis

◇ Y(Y1、Y2)axis: ram synchronous control axis, controlling bending depth and angle control.

◇ X(X1、X2)axis: Control for back gauge front-back stroke, using controlling bending flange size

◇ R(R1、R2)axis: Control for back gauge beam up-down

◇ Z(Z1、Z2)axis: Controlled back gauge finger left-right movement.

◇ V axis: Working table auto-hydraulic crowning control

Electro-hydraulic servo synchronous CNC bending machine has CNC system control, To achieve automatic calculation, a variety of processes to store conversion, Back gauge positioning more accurate, can fold many shaped products

Electro-hydraulic servo synchronous CNC bending machine with the addition of deflection compensation device, it functions: Angle compensation, length compensation and gap error compensation, etc. To ensure the accuracy of the processed parts, reduce the error, greatly improve the twist axis bending machine error, rework more than the phenomenon.

Controller Optional

Optional laser Protection Device

Technical Parameters

Model | Nominal Pressure (KN) | Length of table (mm) | Distance Between Columns (mm) | Throat Depth (mm) | Stroke (mm) | Open Height (mm) | Main Motor (kw) | Overall Dimensions (L*W*H)(MM) |

50T/1300 | 500 | 1300 | 1120 | 250 | 150 | 460 | 5.5 | 1800*1500*2300 |

70T/1600 | 700 | 1600 | 1300 | 300 | 150 | 460 | 5.5 | 2300*1600*2500 |

70T/2500 | 700 | 2500 | 2050 | 300 | 150 | 460 | 5.5 | 3100*1600*2500 |

80T/2500 | 800 | 2500 | 2050 | 300 | 150 | 460 | 7.5 | 3100*1600*2600 |

110T/2500 | 1100 | 2500 | 2050 | 400 | 200 | 490/470 | 11 | 3100*1800*2600 |

110T/3200 | 1100 | 3200 | 2700 | 400 | 200 | 490/470 | 11 | 3800*1800*2600 |

110T/4000 | 1100 | 4000 | 3100/3600 | 400 | 200 | 490/470 | 11 | 4600*1800*2600 |

135T/3200 | 1350 | 3200 | 2700 | 400 | 200 | 490/470 | 11 | 3800*1800*2700 |

135T/4000 | 1350 | 4000 | 3100/3600 | 400 | 200 | 490/470 | 11 | 4600*1800*2700 |

170T/3200 | 1700 | 3200 | 2700 | 450 | 200 | 490/470 | 15 | 3800*2000*2800 |

170T/4000 | 1700 | 4000 | 3100/3600 | 450 | 200 | 490/470 | 15 | 4600*2000*2800 |

220T/3200 | 2200 | 3200 | 2600 | 450 | 200 | 490/470 | 18.5 | 3800*2200*2850 |

220T/4000 | 2200 | 4000 | 3100 | 450 | 200 | 490/470 | 18.5 | 4600*2200*2850 |

250T/3200 | 2500 | 3200 | 2600 | 450 | 250 | 540 | 22 | 3800*2000*2900 |

250T/4000 | 2500 | 4000 | 3100 | 450 | 250 | 540 | 22 | 4600*2100*3100 |

250T/5000 | 2500 | 5000 | 3800 | 450 | 250 | 540 | 22 | 5600*2150*3150 |

250T/6000 | 2500 | 6000 | 4800 | 450 | 250 | 540 | 22 | 6600*2150*3150 |

300T/3200 | 3000 | 3200 | 2600 | 500 | 250 | 570 | 22 | 3800*2250*3200 |

300T/4000 | 3000 | 4000 | 3100 | 500 | 250 | 570 | 22 | 4600*2500*3400 |

300T/5000 | 3000 | 5000 | 3800 | 500 | 250 | 570 | 22 | 5600*2500*3400 |

300T/6000 | 3000 | 6000 | 4800 | 500 | 250 | 570 | 22 | 6600*2500*3400 |

400T/3200 | 4000 | 3200 | 2600 | 500 | 300 | 610 | 30 | 3800*2700*3500 |

400T/4000 | 4000 | 4000 | 3100 | 500 | 300 | 610 | 30 | 4600*2700*3500 |

400T/5000 | 4000 | 5000 | 3800 | 500 | 300 | 610 | 30 | 5600*2700*3500 |

400T/6000 | 4000 | 6000 | 4800 | 500 | 300 | 610 | 30 | 6600*2700*3500 |

500T/4000 | 5000 | 4000 | 3100 | 500 | 300 | 620 | 37 | 4600*2700*3500 |

500T/5000 | 5000 | 5000 | 3800 | 500 | 300 | 620 | 37 | 5600*2700*3500 |

500T/6000 | 5000 | 6000 | 4800 | 500 | 300 | 620 | 37 | 6600*2700*3600 |

600T/5000 | 6000 | 5000 | 3800 | 600 | 320 | 650 | 45 | 5600*3300*3900 |

600T/6000 | 6000 | 6000 | 4800 | 600 | 320 | 650 | 45 | 6600*3300*3900 |

600T/7000 | 6000 | 7000 | 5600 | 600 | 320 | 650 | 45 | 7600*3300*3900 |

800T/6000 | 8000 | 6000 | 4600 | 600 | 320 | 800 | 30×2 | 6600*3500*4000 |

800T/7000 | 8000 | 7000 | 5600 | 600 | 320 | 800 | 30×2 | 7600*3500*4200 |

800T/8000 | 8000 | 8000 | 6600 | 600 | 320 | 800 | 30×2 | 8600*3600*4500 |

800T/10000 | 8000 | 10000 | 7800 | 600 | 320 | 800 | 30×2 | 10600*3600*4900 |

Copyright 2023 © All rights Reserved. Design by Beboss