Bending center equipment, also known as flexible bending center, also known as fully automatic multilateral bending center, can be folded a variety of complex shapes, easy to achieve the arc, pressure dead edge, back to the shape, closed shape and other complex sheet metal bending requirements.Fully Automatic Bending Center System is a CNC machine specially designed for sheet metal bending, which realizes the full automation of sheet metal bending through the functions of multi-axis concurrent linkage, automatic loading and unloading, and automatic adjustment of bending parameters.The system is widely used in many industries such as chassis cabinets, home appliances, automobiles, kitchenware, building decoration, etc. It is one of the important equipments in the field of metal processing.

The main parts of the fully automatic bending center system are composed of:

1.Frame and bed: as the support structure of the whole system, it ensures the stability and precision of the equipment.

2.Servo system: including servo motors and servo controllers, etc., to achieve precise control of the bending action.

3.Hydraulic system: Provides the pressure and power required for bending.

4.CNC system: as the core control part of the system, it is responsible for receiving and processing the bending commands and controlling the cooperative work of each component.

5.Molds and fixtures: used to clamp and position the plate to ensure accuracy and stability of the bending.

6.Automatic loading and unloading system: Realize automatic loading and unloading of plates to improve production efficiency.

Main features:

1.Highly automated:

The fully automatic bending center system can automatically complete all processes of plate clamping, positioning, bending and unloading without manual intervention. This not only reduces labor intensity, but also improves productivity and safety.

2.High precision and quality:

The bed of the Intelligent Flexible Bending Center adopts a high-precision temperature-controlled furnace for tempering heat treatment, as well as full-frequency vibration aging treatment to ensure that there is no deformation in long-term use, thus guaranteeing the stability of the bending precision and the system’s comprehensive accuracy. The application of angle correction database and servo-electric technology further enhances the bending quality.

3.Efficient and flexible:

The machine is capable of automatically creating a variety of bends for each side, including up-and-down, flat, or curved bends, and it supports customized bending motions, allowing advanced commands to be inserted at any step to perform the various motions required. Fast bending speeds, capable of bending at 0.2 sec/knife, and completing a workpiece every 30 seconds, support 24/7 production, and are particularly suitable for high-volume production.

4.Easy to operate and maintain:

Intelligent flexible bending center is equipped with friendly man-machine interface, easy to learn programming, easy to operate. Daily maintenance workload is low, with the entire self-lubricating system, the system automatically warns when the oil volume is lower than the value, only need to increase the lubricating grease in accordance with the program prompts.

5.Broad compatibility:

The equipment has rich hardware and software interfaces, which can be docked to the conventional robotic arms on the market, compatible with various loading and unloading methods, such as manual loading and unloading, truss robot loading and unloading, robotic arm loading and unloading, and so on.

6.Energy saving and environmental protection:

The use of a purely electric servo system to replace the traditional hydraulic drive not only provides environmental performance advantages, but also faster speeds and higher precision, while eliminating the need for cumbersome maintenance.

The technical advantages of intelligent flexible bending centers:

1.No mold required:

The Intelligent Flexible Bending Center uses a universal bending mold, eliminating the need to re-make molds for each type of bending workpiece, reducing mold costs and shortening production time.

2.Multi-axis concurrent linkage:

The equipment supports concurrent linkage of multiple axes, smooth bending action, high synergy of mechanical operation, and can successfully complete a variety of complex action combinations.

3.Intelligent control system:

Equipped with advanced control system, it has the functions of off-load detection, off-load follower, thick plate detection, etc., which effectively protects the machine and workpiece and reduces the waste of workpiece. The cloud-based operation and maintenance management system can monitor the machine operation in real time to ensure the stability and reliability of the production process.

Technical basis and development trend of bending center:

Bending center is a set of mechanical, electrical, control and other multidisciplinary technology in one of the comprehensive equipment, mainly used for bending sheet metal parts processing. In recent years, with the rapid development of the manufacturing industry, the technical requirements of the bending center is also increasingly high. Intelligent, automated, efficient bending center technology has become the main trend of development.

1.Intelligent: Through the introduction of artificial intelligence, big data and other technologies, the bending center achieves precise control and optimization of the bending process. The intelligent control system can monitor the processing status in real time and automatically adjust the processing parameters to ensure processing accuracy and efficiency.

2.Automation: Bending centers have gradually realized full automation from material loading, positioning, bending to unloading. The application of automation technology not only improves production efficiency, but also reduces labor intensity and enhances the safety of the working environment.

3.Efficient: By optimizing the machine structure and control system, the bending center has significantly increased the processing speed while maintaining high processing accuracy. Highly efficient bending centers can better meet the needs of large-scale and batch production.

Areas of application:

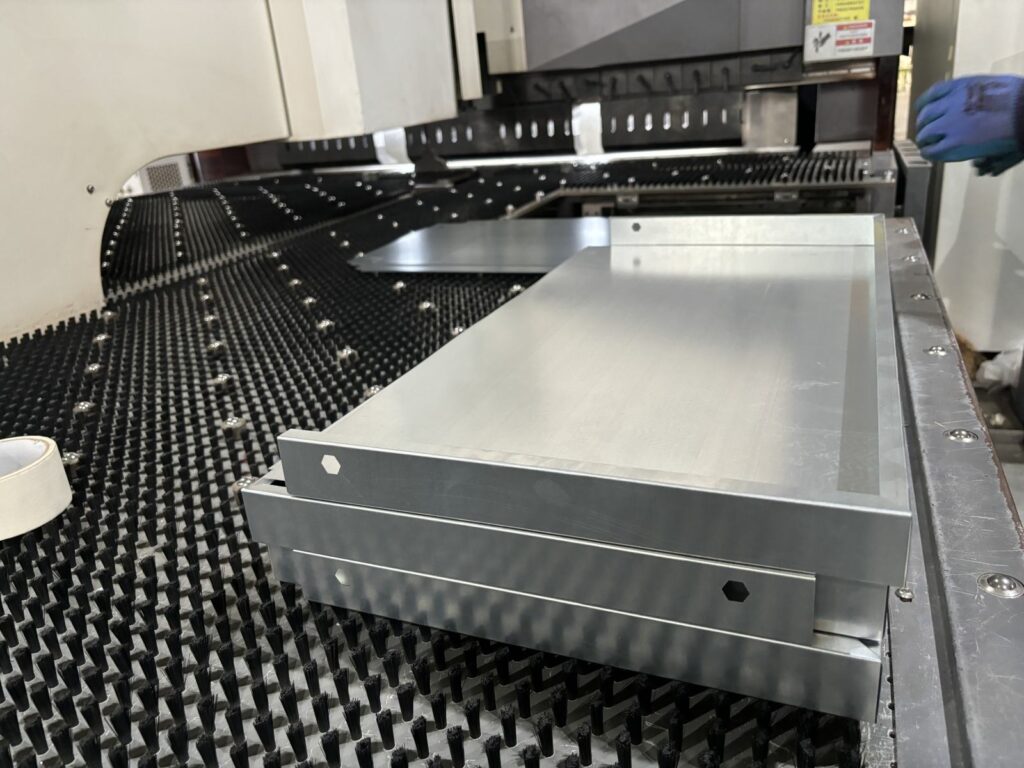

The Intelligent Flexible Bending Center is widely used in steel cabinet shells (such as filing cabinets, tool cabinets, electrical cabinets, etc.), kitchenware, furniture, ventilation, refrigeration, purification, doors, decorations, elevators, and other related metal forming fields. It can meet the bending needs of different types of workpieces and is suitable for a variety of complex metal forming processes.

A typical example of the application of intelligent flexible bending center technology:

1.Automobile manufacturing field:

In the process of automobile manufacturing, a large number of sheet metal parts need to be bent. Bending centers are widely used in the automotive manufacturing field by virtue of their high precision and high efficiency.

2.Aerospace:

The aerospace industry requires a high degree of precision and stability from its bending centers. Flexible bending centers have been successfully used in the sheet metal processing lines of many aerospace companies due to their excellent performance. The equipment not only improves processing accuracy and efficiency, but also reduces production costs, bringing significant economic benefits to the enterprise.

3.Electronic and electrical fields:

Bending centers also play an important role in the field of electronics and electrical appliances. For example, the project of special robot bending cell for high and low voltage switchgear industry has successfully realized automated bending production. The project not only improves production efficiency and product quality, but also reduces labor intensity and safety risks, which has won a good market reputation for the enterprise.

Summarize:

Intelligent Flexible Bending Center plays an important role in the field of metal forming with its high precision, high efficiency, easy operation, wide compatibility and energy saving and environmental protection. It is a high-tech product developed and produced for the sheet metal industry to improve productivity, reduce labor intensity, lower labor costs and enhance corporate image. It can not only meet the bending needs of various complex workpieces, but also in the filing cabinets, electrical cabinets, doors, tool cabinets, kitchen utensils, ventilation, air-conditioning, purification, education, experimental equipment and other industries have been widely used, greatly improving the production efficiency of sheet metal products and product consistency, but also reduce the labor intensity of the workers, to bring significant economic and social benefits for the enterprise.