Working principle of CNC grooving machine:

CNC grooving machine is a high precision and high efficiency machine tool, which controls the tool to perform the grooving operation on the workpiece through the CNC system. Its working principle is that, according to the pre-programmed program, the CNC system sends out commands to drive the tool to move according to the set trajectory, so as to realize the precise processing of the workpiece.The tool is usually mounted on a movable tool holder, which is driven by a power unit such as an electric motor and reciprocates on the plate according to a set program to remove excess metal material to form the desired groove. Accurate machining of the groove can be realized by precisely controlling the movement trajectory and cutting depth of the tool. As an important metal processing equipment, groove planer shows its wide application value and significant advantages in many fields.

Functional characteristics of CNC grooving machine:

1.High-precision machining: CNC groove planer adopts advanced CNC system and precise mechanical structure, the tool system and control system of groove planer can accurately control the cutting depth and width, and it can realize micron-level machining accuracy to meet the machining needs of high-precision parts. This is critical for those areas that require extremely high machining accuracy, such as aerospace, electronics and electrical appliances.

2.Diversified processing capability: in addition to straight line processing, CNC groove planer can also be programmed to realize the processing of curves, arcs and other complex shapes. This is thanks to its powerful interpolation function and rich tool library, which makes the machining process more flexible and diversified.

3.High efficiency production: CNC groove planer has the characteristics of high degree of automation, fast processing speed etc. CNC system can automatically optimize the processing path, reduce the empty travel time, improve the processing efficiency and reduce labor costs.

4.Efficient and time-saving: grooving machines have an efficient machining capacity and can quickly complete a large number of machining tasks. Compared to traditional manual chiseling and drilling, the planer can significantly increase efficiency and save time and costs.

5.High degree of automation: CNC groove planer accurately controls the movement of the tool through the computer numerical control system, and the operator only needs to input the corresponding parameters to realize automatic processing. Equipped with an intuitive touch screen operation interface, users can complete the machining task with simple settings, which reduces the difficulty of operation. This not only reduces the difficulty and labor intensity of manual operation, but also improves the accuracy and stability of machining.

6.Strong versatility: the grooving machine can process metal materials of various thicknesses and sizes to meet the needs of different users. Meanwhile, it can also be used for concrete, asphalt and other construction materials in different working environments, with wide applicability.

7.Reduced Labor Costs: As a one-time investment, slot planers can significantly reduce labor costs compared to hiring workers to manually cut or drill holes.

Practical application of CNC grooving machine:

It is suitable for precision machining of metal materials. For example, CNC groove planer plays an important role in the fields of mold manufacturing, auto parts processing, aerospace and so on. Through programming control, it can easily cope with the processing tasks of various complex shapes, providing strong support for the development of modern manufacturing industry.

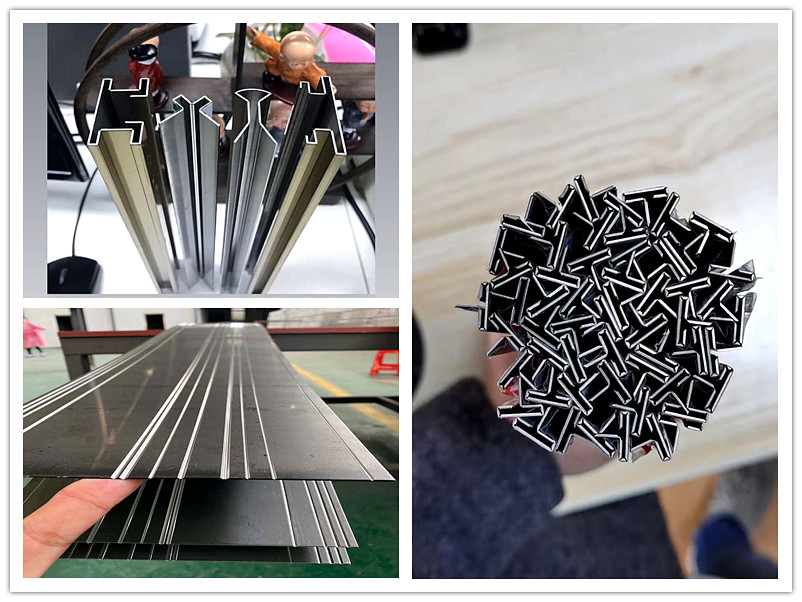

1.Metal processing: grooving machine plays a vital role in the processing of metal plates, whether it is ordinary grooving machine or CNC grooving machine, it can process stainless steel, carbon steel, aluminum alloy and many other metal materials with high efficiency and precision.In the production of stainless steel cabinets, aerospace parts manufacturing, and processing of electronic and electrical components, the groove planer provides a strong guarantee for the quality and performance of metal products with its high precision and high performance.

2.Building decoration: groove planers have an equally important place in the building decoration industry.Whether it is high-level architectural decoration, brand display store decoration, hotel decoration, or stainless steel decorative works in stations, subways and other public places, slot planer can quickly and accurately complete a variety of groove processing, adding a unique charm to the building.

3.Roads and Bridges:In the field of road and bridge construction, the grooving machine is mainly used to cut and plane roads, highways, bridge piers and other structures. Its high speed and precise machining capability can quickly complete the excavation of roadway slots and subway tunnels, and improve the quality and precision of bridge construction.

4.Mold Manufacturing: In the process of mold manufacturing, CNC groove planer can be used to process mold cavities, cores and other parts of the mold to improve the precision and durability of the mold.

5.Aerospace: In the aerospace sector, CNC groove planers can be used to machine high-precision components, ensuring that the quality and performance of the product meets stringent requirements.