CNC slotting machine is suitable for elevators, decorative materials, stainless steel processing, household appliances, high-end anti-theft doors, high-end copper doors, curtain walls and other industries that require high-precision processing of plates.Welded steel plate structure, annealing aging treatment, good stability, high working precision, high processing efficiency, and greatly reduce the labor intensity of workers.

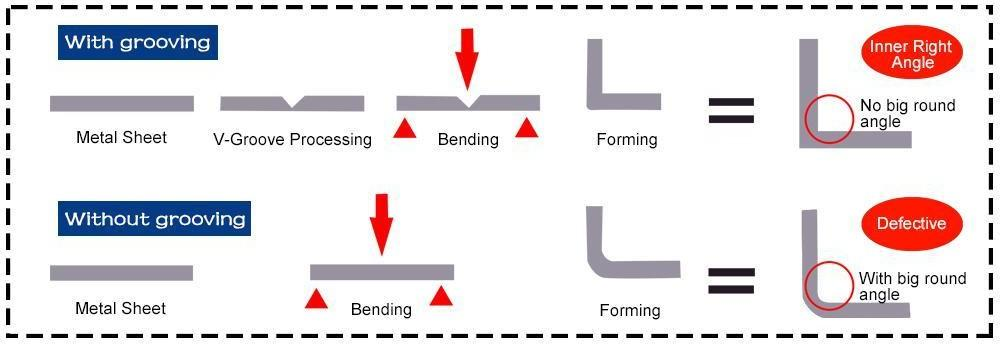

Grooving is an auxiliary process of metal or non-metallic material bending molding, in the metal or non-metallic materials need to bend molding of the bending line at the use of special equipment and cutting tools planing V-shaped groove, so that the material is easy to bend the molding and the bending angle of the outside of the R can be minimized, and then use the bending machine or hand-bending molding, so that the processing is completed to achieve the appearance of the product requirements.The depth, width and angle of the V-groove can be ensured by the amount of feed and the shape of the planer knife during the creation of the cut.

Vertical CNC grooving machine structure features:

The workpiece is clamped by the hydraulic clamping device and driven by the servo motor to move back and forth relative to the worktable for the positioning of the grooving position, and then the hydraulic pressure device fixes the grooving. The machine tool adopts frame structure and high strength bolt connection, with good overall rigidity and small deformation.The machine is equipped with special numerical control system, easy to program and operate, easy to learn and use. The workpiece is fed from the front side of the machine, hydraulic clamping, stable and reliable pressing, convenient and quick operation. The groove position is determined by servo-driven, double-screw synchronous transmission, accurate positioning and good parallelism. The worktable is equipped with material support devices at the front and rear, effectively preventing scratches in the process of plate processing.The feed of tool holder is servo-driven, the planing groove is guided by high-precision double linear guides, realized by rack and pinion transmission, speed adjustable, good rigidity, low resistance, smooth movement, high precision of feed and movement, energy-saving and high efficiency.

Gantry CNC grooving machine structure features:

Gantry type CNC slot planer machine base and beam are designed with frame structure, through sand blasting treatment and heat treatment process, the overall rigidity is good, high strength, not easy to be deformed in long term use, and it adopts large-scale CNC gantry machining center for one-time precision machining to complete, with high precision and stability, and long service life.The tool holder adopts V-groove sliding clearance adjustable structure, ductile casting material, high strength, high wear resistance, better guidance. Convenient loading and unloading, air-cooling without environmental pollution, servo full control, realizing full-automatic operation and processing, improving the precision of groove planing processing.Adopting hydraulic control system as power, high pressure, reliable fastening force, low noise and low energy consumption. Adopting fine grinding gears, 45# steel forging tempered rack and pinion guide transmission, moving speed can be adjusted frequently, cutting process is smooth. CNC program design is reasonable, easy to grasp, only need to enter the processing size can be completed.The body of this machine is fixed, helical gear, rack and pinion drive beam movement, moving speed can be adjusted steplessly, the cutting process is smooth and efficient, low noise, cutting surface is flat and smooth. According to different materials, the processing speed can be adjusted by knob, which is easy for operators to operate.

Types of grooving machines:

1.Laser slotting and laminating machine:

Laser slotting laminating machine, with laser, slotting double position. Full servo control, high precision of laser and grooving. Save processing time, save labor site cost.

2.Fully automatic four-side grooving machine:

The tool holder is equipped with automatic rotating function and accurate positioning, and can groove in both vertical and horizontal directions. Vertical and horizontal dual servo motors, accurate positioning, slotting efficiently and stably. Full-automatic longitudinal and transverse grooving, no need for customers to rotate the workpiece, full-automatic one-time molding, door industry processing tool.

3.High-speed model grooving machine:

Beam type cutting, double guide rail structure, smooth running of the beam, stable and efficient work. Four-axis servo control, accurate positioning, high-precision industrial touch screen, easy to operate. 45 steel worktable, table precision to 0.03mm. universal tool clamping mounting surface, can be white steel knife alloy knife interchangeable use.

4.High-speed split model groove planer:

Separate operation by machine control, can edit the next program while grooving, saving processing time.

5.High-speed unidirectional vertical machine:

The working table is equipped with one-piece high-frequency quenching base film, which has high hardness, long service life, and does not leave marks when processing mirror material. Fixed presser feet and rear feeding clamps are arranged in intervals, evenly and densely distributed. The rear feeder is driven by double screws and double guide rails, with smooth operation and accurate positioning. High-power spindle servo motor, high-speed and stable grooving.

6.High-speed back and forth planing vertical machine:

Dual tool holders, back and forth grooving, make full use of the return power and time, improve the grooving efficiency, save the user processing time.