The working principle of CNC slotting machine:

CNC grooving machine controls the tool to groove on the surface of the workpiece through the CNC system. Its working principle is to fix the workpiece on the machining table, and then the CNC system according to the pre-set processing procedures, through the control of the tool’s trajectory and speed and other parameters, through the high-speed rotation of the tool to cut the workpiece, to achieve the workpiece grooving processing.The tool is usually a rotating circular saw blade or cutter wheel, driven by an electric motor to rotate, the workpiece to be cut will be fixed on the table, through the movement of the table to achieve different directions and depths of cut.The cutting accuracy of the grooving machine depends on the rotational speed of the tool and the depth of cut, the higher the rotational speed of the tool, the higher the cutting accuracy; the deeper the depth of cut, the greater the cutting force, the cutting efficiency is also increased accordingly.

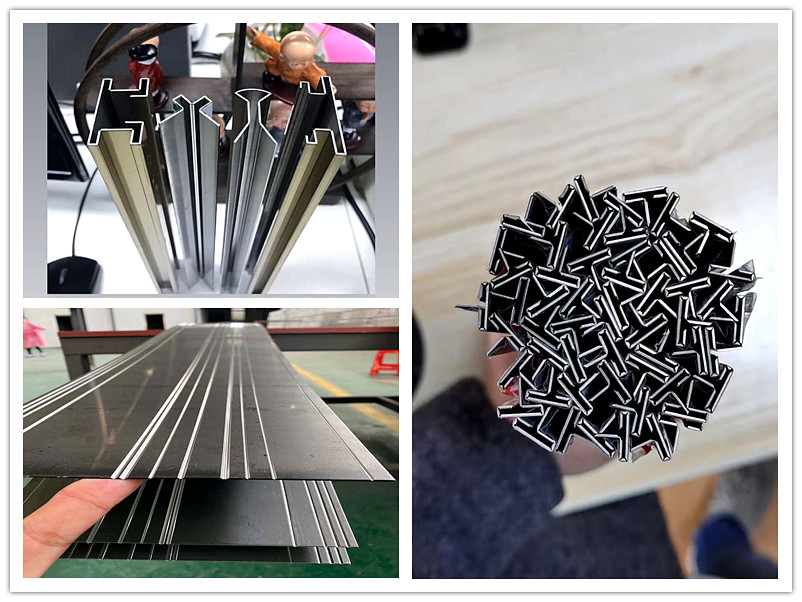

Structural features of CNC slotting machine:

CNC grooving machine includes frame, CNC system, cutting tool, cutting system and other components. The cutting system is the core component of the grooving machine, which usually consists of cutting head, cutting tool, guide rail and other parts.The cutting head is the key component to realise the cutting function, which usually consists of motor, reducer, cutter disc, blade and other parts, and can realise high-speed cutting. The cutting tool is an accessory of the cutting head, usually with a variety of specifications and models to choose from.The guide rail, on the other hand, is the trajectory of the cutting head, which usually adopts high-precision linear guide rails to ensure cutting accuracy and stability.Among them, the frame is the most core part of the CNC slotting machine, and its main structure includes the bed, column, working table, tool holder and so on. The frame is usually welded from steel plate and steel pipe with enough strength and rigidity to support the whole machine.CNC system is the core component to control the CNC grooving machine to complete the machining task, it includes computer, CNC software, control card and so on. Tool magazine is the equipment for storing tools, which can automatically change tools and improve machining efficiency.The movement of the crossbeam is made by linear rolling guide and ball screw, equipped with servo motor to achieve low resistance to movement and high displacement accuracy. The movement of the tool holder adopts linear rolling guideway and frequency conversion speed control motor to provide adjustable moving speed to ensure low feeding resistance and high feeding precision. Workpiece clamping adopts pneumatic automatic clamping device, realising automatic lubrication, easy operation and high working efficiency.

Areas of application for CNC grooving machines:

CNC slotting machine is widely used in manufacturing industry, steel, construction, machinery especially in metal processing. It can be used to manufacture a variety of products, such as automotive parts, mechanical parts, electronic product shells and so on. Compared with the traditional processing method, CNC slotting machine has the advantages of high processing precision, high processing efficiency and good working environment.

1.Steel processing:

In the field of steel processing, grooving machine is mainly used to cut materials such as steel plate and steel pipe to meet different processing requirements. It can achieve high-speed and high-precision cutting, which can greatly improve the productivity and product quality.

2.In the field of construction:

In the field of construction, grooving machine is mainly used to cut various building materials, such as stone, glass, ceramics and so on. It can achieve various complex cutting shapes to meet different architectural design requirements.

3.Mechanical engineering:

In the field of machinery manufacturing, grooving machine is mainly used to cut various mechanical parts, such as wheel grain, gears, bearings and so on. It can achieve high-precision cutting and processing, which can greatly improve the quality and performance of mechanical parts.