Process Preparation:

The making of a bending machine starts with the design. Designers will draw various machine drawings according to the needs of different customers. When drawing the drawings, you need to consider the design of the machine’s structure, electrical control system, transmission system and other aspects of the design. During this stage, the designer needs to communicate with the customer to ensure that the bending machine is designed to meet the customer’s needs.

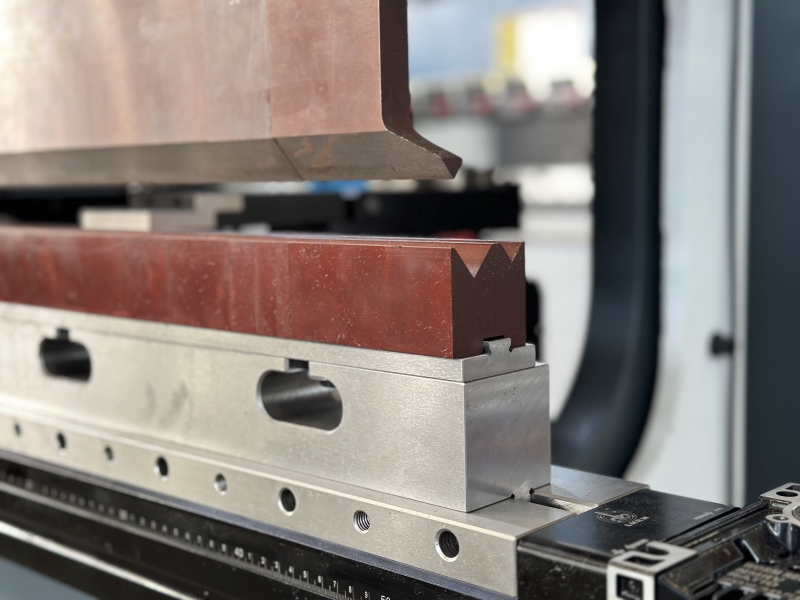

1.According to the required bending work piece, select the appropriate press brake tool.

2.Installation of the press brake tools requires strict adherence to the operation manual to ensure the stability and accuracy of the press brake tools.

3.Inspect the bending machine to keep the equipment clean and in good working order.

Machining process:

Processing technology is the core of bending machine press brake tool processing, mainly including milling, turning, cutting, drilling, cold work, heat treatment and other processes.For different kinds of press brake tools, different machining processes are required. In the processing process, it is necessary to fully consider the processing accuracy, surface quality, production efficiency and worker safety and other factors.

Material processing:

Rough machining of press brake tool steel, after heat treatment and softening, rough machining according to the design drawings, including milling, planer planing, wire cutting and so on. press brake tool steel finishing, rough machining after finishin Guide pillar and guide sleeve processing, according to the design requirements for precision machining, to ensure the relative positioning accuracy of the guide pillar and guide sleeve. Spring processing, according to the design requirements for the production of press brake tool springs, to ensure the resilience of the press brake tool performance.g, to ensure the accuracy and surface finish of the press brake tool.Fastener processing, according to the design requirements to make fasteners, to ensure the assembly and adjustment of the press brake tool.

Heat Treatment:

press brake tool steel heat treatment, according to the material characteristics of the press brake tool steel, appropriate heat treatment, such as quenching and tempering, etc., to enhance the hardness and wear resistance of the press brake tool. Heat treatment of guide pillar and guide sleeve, according to the material requirements for heat treatment, such as nitriding or surface treatment, etc., to enhance the surface hardness and wear resistance.

Assembly:

According to the design drawings and assembly process requirements, assemble the machined parts. Install the press brake tool on the bending machine. And make fine adjustments to ensure the precision and positioning accuracy of the press brake tool.

Trial press brake tools:

Conduct a trial press brake tool to check the precision and performance of the press brake tool, whether there are problems such as poor product formation and press brake tool wear. Make necessary adjustments and modifications according to the trial press brake tool situation.

Machining operations:

After the machine drawings were completed, it was time to move on to the machining and fabrication phase. The whole structure needs to be machined and welded. The bending machine consists of frame, cylinder, coiler and other components. The frame is usually manufactured from high quality steel and heat treated or passivated to enhance its durability and corrosion protection.Cylinders are used in conjunction with the hydraulic system to drive the upper and lower press brake tool boards to complete the up and down movement. Cylinders also need to implement the requirements of leakage detection, and strict processing inspection. Rolling machine is mainly used for roll pressing metal materials, in the production of different plate thickness needs to be selected for the:

1.According to the required work piece size and bending angle, set the parameters on the bending machine.

2.Adjust the clamping block of the bending machine to ensure that the work piece is clamped firmly.

3.Start the bending machine and carry out the bending operation. In the operation, pay attention to the control of bending speed and pressurizing force to avoid deformation and errors in the work piece.

Corner Adjustment:

1.During the bending process, observe the angle and turning of the work piece at all times.

2.When the work piece has corner deviation, it should be adjusted in time to ensure the accuracy of the work piece.

Positioning calibration:

After the assembly of the bending machine is completed, various tests need to be carried out. This phase can be categorized into testing sessions such as no load, load, calibration and programming.The purpose of testing is to assess the performance and reliability of machines and to adjust and optimize them. During testing, technicians need to thoroughly inspect each component to confirm that they meet standards and work together.

1.At the end of bending, the positioning calibration should be carried out to check the accuracy and dimensional precision of the work piece.

2.If there is any deviation, it should be adjusted and reworked in time.

Follow-up processing:

After completing the bending process, the products need to undergo subsequent treatment. It mainly includes de burring, grinding, polishing and other processes to improve the product surface quality. In the follow-up treatment process, attention needs to be paid to ensure the flatness of the product surface and the precision of the detail treatment.

Cleaning and maintenance:

1.After daily use, clean the bending machine and refill the lubricant.

2.Maintain the bending machine on time, check the parts of the machine and keep the equipment in good condition.

Caveats:

1.Before operation, conduct a safety check to prevent injuries caused by accidental operation.

2.Operate in a safe manner, especially at moderate pressure, to avoid explosion and other hazards.

3.In the process of using, pay attention to keep the environment clean, and maintain and organize the operation platform to keep the operation environment neat and tidy.