Sheet metal processing is an indispensable part of machining, especially in the aviation, home appliances, automotive, elevator and other industries, sheet metal parts are widely used.Bending process, as the only single forming process in sheet metal processing, is one of the most important processes in sheet metal processing, and a good or bad bending process will have a direct impact on the forming size and appearance of the product.Therefore, how to ensure the forming size and angle of the work piece in the bending process is a key research in the bending process.

Limitations of traditional bending methods:

The traditional bending process is under the pressure of the upper and lower molds of the bending machine, the use of the two prongs of the lower mold opening and the top of the upper mold prongs of the sheet metal bending, sheet metal by the elastic deformation to the process of plastic deformation. The bending angle is determined by the depth of the upper mold into the lower mold.Now people have higher and higher requirements for the shape of the work piece, some of the complex shape of the work piece, the use of traditional free bending, bending machine bending and even three-point bending process has been unable to bend, and the traditional bending method can not control the size of the radius of the corner of the bending, it is difficult to achieve the process of bending the requirements of the non-marking bending.Therefore, an emerging bending process – planer bending process came into being.

Characteristics of the planing and bending process:

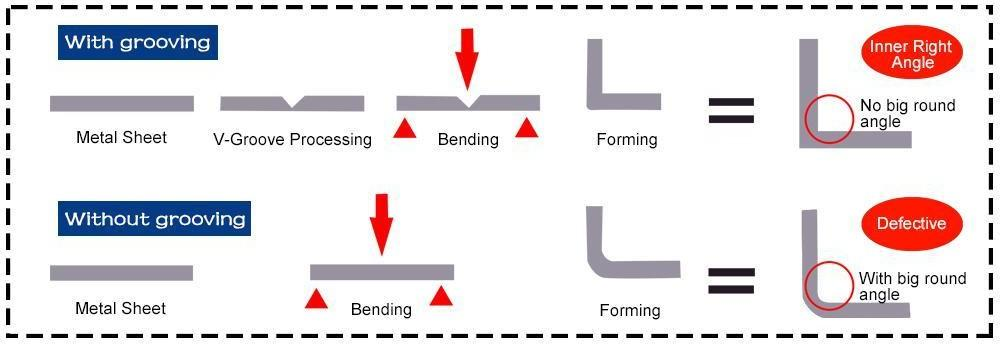

Grooving bending process is a kind of grooving machine in the sheet metal to be bent on the location of scribing planing V-shaped groove, and then according to the needs of the ordinary bending machine bending process. The characteristics of the planing and bending process mainly include the following three aspects.

The arc radius of the edges of the work piece is small and the work piece is free of creases:

From the bending process can be seen, the size of the radius of the edge of the work piece after bending and the thickness of the plate into a proportional relationship, the thicker the plate, the greater the radius of the arc formed by bending. V-shaped grooving of sheet metal, the remaining thickness of the plate becomes half of the original, or even smaller, so that the work piece can make the radius of the arc of the edge after bending is greatly reduced.And because of the thin plate thickness remaining at the bending place after grooving, the deformation force during bending will be reduced accordingly, and will not spread to the unbending area, so there is no crease on the surface of the work piece after bending, and because of the thin thickness of the plate at the bending place, the reduction of the pressure required during bending can avoid the risk of indentation on the decorative surface very well.

This can meet the process requirements of small radius of work piece edges, no crease on the surface and no indentation on the decorative surface in the metal decoration of hotels, banks, commercial centers, airports and other high-grade places.

Reduced equipment tonnage required for plate bending:

In the bending process, the bending force required for sheet metal is directly proportional to its thickness. The greater the thickness of the sheet metal, the greater the required bending force, the required equipment tonnage is also correspondingly higher.In the bending of sheet metal before the bending of the V-shaped planing groove, so that the remaining thickness of the plate is greatly reduced, so that the plate bending the bending force required will be reduced accordingly, so that the thick plate can be in the smaller tonnage of the bending machine for bending. This not only reduces the investment in equipment, but also saves energy and space.

Bending of complex shaped work pieces and control of rebound force:

Many complex work pieces can not be bent on the general bending machine, but the bending of the part can be realized by opening a V-shaped groove in the bending place and then bending the part by hand.In addition, the control of rebound force and rebound angle can be realized by controlling the remaining thickness of the plate. If the remaining plate thickness after grooving is controlled to be about 0.3mm, the rebound angle can be made very small and the rebound can be basically ignored.

How to avoid deviations in bending angles and dimensions:

For the bending process, the good or bad bending molding mainly depends on the bending angle and size of these two important parameters. When bending, in order to ensure that the bending of the molding size and angle, need to pay attention to the following aspects of the problem.

1. Upper and lower mold cutter centering is not the same, will lead to errors in bending size, bending before the need for upper and lower mold cutter centering adjustment.

2. After the block left and right position of the block to move, the relative position of the sheet and the lower mold may change, thus affecting the bending size, bending before the need to re-measure the distance between the position of the block.

3. The work piece and the lower mold parallelism is not enough, will cause bending rebound, affecting the bending angle, the need to measure and adjust the parallelism before bending.

4. A bending angle is not enough, the second bending will also be affected, the accumulation of bending errors will lead to increased size and angle of the work piece molding error, so it is particularly important to ensure the accuracy of one-sided bending.

5. When bending, the size of the lower die V mouth and bending pressure is inversely proportional to the processing of different thicknesses of sheet metal, you need to select the appropriate lower die V groove according to the regulations, generally choose the most appropriate 6 to 8 times the thickness of the plate.

6. When the work piece is bent on the bending machine after planing the V-groove, it is necessary to ensure that the edge of the upper mold, the bottom edge of the V-groove of the work piece and the bottom edge of the V-groove of the lower mold are on the same vertical plane.

7. When bending the work piece after planing the groove, in order to prevent clamping the knife, the upper mold angle is best controlled at about 84 °.

Detailed description of the planing and bending process:

Processes:

1. Material Preparation: Firstly, the metal sheet to be processed will be finely cut and polished to ensure that the surface of the material is flat and smooth.

2. Drawing design: According to the actual needs, design the required planing and bending dimensions, and formulate the processing technology program.

3. Grooving: Use the grooving machine to carry out the grooving process of the metal plate, and accurately complete the line guidance required in the drawings.

4. Bending: according to the drawing requirements and processing programs, the use of bending machines for accurate bending processing.

5. Welding: If the drawings need to weld multiple metal plates together, you can use the relevant welding equipment for processing.

Caveats:

1. Pay attention to the fine cutting and grinding of metal sheets to ensure that the surface is flat and smooth so as not to affect the subsequent processing.

2. Keep the normal operation of the equipment, and pay attention to safety matters, processing must wear the relevant safety equipment.

3. According to the actual demand and processing program, correctly use the grooving machine and bending machine to ensure the processing quality.

4. Adopt different welding techniques according to the different characteristics of metal materials to ensure the strength and stability of the welded parts.

Common problems and solutions:

1. The planing groove is not deep enough or uneven: you need to adjust the equipment of the planing groove machine and pay attention to the use of the cutting kerf.

2. Inaccurate bending angle: need to adjust the pressure of the bending machine, or replace the different size of the mold.

3. Surface scratches or deformation: may be due to improper processing in the planing groove or bending process, need to double-check the equipment and processing methods.

4. Welding cracks or leakage: need to replace the wire or increase the welding time and temperature to ensure the quality of welding.