Bending is the process of turning a flat sheet of metal into three dimensions by means of pressure equipment and special press brake tools is called bending.Due to different materials, thickness, length, width of the plate and the need to form different shapes and angles, so there are different tonnages and sizes of pressure equipment bending machine, with different heights, shapes, V width size of the upper and lower die to its special shape of the special press brake tools.Nowadays, sheet metal processing enterprises have higher and higher requirements for the forming accuracy and shape complexity of sheet metal products, as well as higher and higher requirements for the surface quality of sheet metal parts, especially for the bending processing of stainless steel and aluminium plates, which are required to be free from scratches.The press brake tools for bending have also changed a lot, from the basic upper and lower press brake tools to the current non-marking press brake tools and so on.

- V-press brake tools:

The V-shaped press brake tools is a common bending machine press brake tools, commonly used for processing steel plates and angle iron and other materials with a small taper. Its name comes from its cross-section is V-shaped, both sides into a 45-degree angle, used to bend the material can be relatively uniform bending angle.

- U-shape press brake tools:

U-shaped die is a commonly used bending machine tool, its cross-section is U-shaped, in the processing of punching or some small curvature of the bending work piece is more commonly used.U-shaped die of the two sides of the angle of 90 degrees, can effectively prevent the work piece to the two sides of the drift.

- Square press brake tools:

Square press brake tools have a square cross-section and are suitable for bending thin plates or work pieces with a large width, with an angle of 90 degrees on both sides, especially suitable for processing square or rectangular work pieces.

- Arc press brake tools:

Arc press brake tools is a kind of press brake tools with circular cross-section, which is suitable for work pieces with small bending radius. Due to the different degrees of the arc, there are different types of arc press brake tools, which can be selected according to the size of the work piece bending angle.

- Conical press brake tools:

Tapered dies are suitable for the processing of convex and concave work pieces and are generally divided into internal and external tapered dies. When bending a work piece, the inner taper die can be referred to as the “convex part”, while the outer taper die can be referred to as the “concave part”.

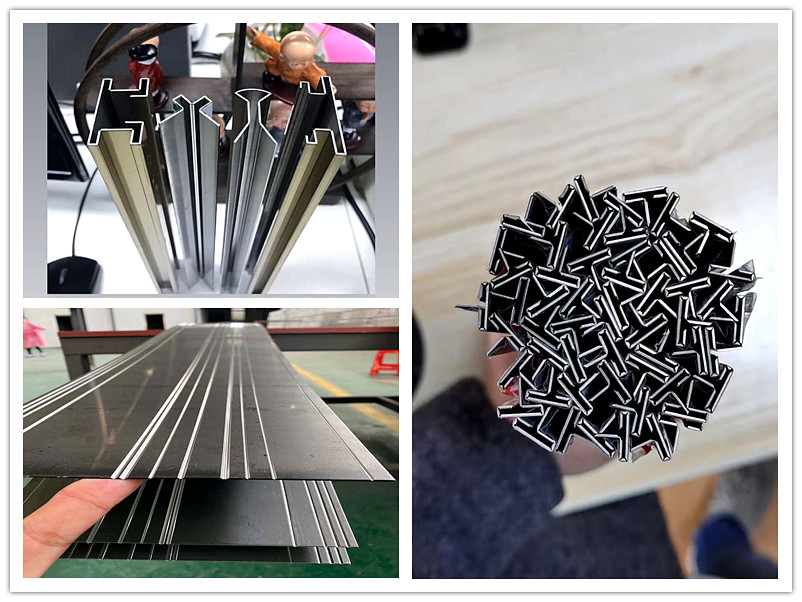

- press brake tools with profile type:

This type of press brake tools is suitable for bending metal materials with specific models. The press brake tools are usually marked with the corresponding model number, which makes it easy for users to identify and select. These press brake tools can be used to produce horizontal channels, Z-beams, H-beams and other shapes.

- Symmetry press brake tools:

A symmetrical press brake tools is a common type of press brake tools. It can bend metal materials at both ends and present a symmetrical shape in the middle. This type of press brake tools is more versatile and suitable for bending and processing of metal materials of different shapes, such as angle steel, flat steel, round steel, etc.

- Multi-combination press brake tools:

Multi-combination press brake tools refer to a group of different press brake tools that can be selected in combination as required to meet different metal processing needs. The advantage of multi-combination press brake tools is easy to change and flexible to use. It is suitable for processing products with a single shape, such as angle steel, flat steel and so on.

- Circular press brake tools:

Circular press brake tools are usually used to process metal products that require curvature. The press brake tools have different radius of curvature and can be selected according to the product requirements. Circular press brake tools are usually used to process curved plates, such as steel skeletons for tunnels.

- Special type press brake tools:

Special type press brake tools are press brake tools that are tailor-made according to product requirements. This type of press brake tools can meet special processing needs, such as processing products with special opening requirements.When choosing a press brake tools, you need to consider the shape, size and demand of the product to choose the right type of press brake tools. When using the press brake tools, you need to operate according to the instructions of the press brake tools to ensure the processing quality and efficiency.

- Ball non-indentation press brake tools:

In the metal plate bending process, the work piece in the bending process and the lower die on the tungsten carbide mandrel contact, and the mandrel will be rotated in the direction of movement of the plate, so that the work piece in contact with the lower die force from the traditional sliding friction into rolling friction, significantly reducing the surface of the work piece due to extrusion of the indentation and abrasion, and effectively improve the appearance of the work piece quality and accuracy. However, in the bending process, the lower die roller and the plate still exists extrusion pressure, can not completely avoid bending indentation, especially in the bending of soft material plate.

- Tension spring type non-indentation press brake tools:

In the process of the upper die pressing the work piece into the lower die body, due to the plane contact between the work piece and the rotating flap, the rotating flap rotates in the lower die body, the work piece does not produce relative sliding with the rotating flap in the whole bending process, and at the same time, the work piece and the rotating flap are in face contact, so as to eliminate indentation and abrasion of the surface of the work piece due to extrusion, and to effectively improve the quality of the appearance of the work piece and its precision.

- Urethane anti-indentation press brake tools:

Can be used through the use of anti-indentation rubber pads, single V concave die anti-indentation rubber sleeve, block of Urethane + AT liner, hard rubber concave die and other methods to solve the indentation of the surface of the work piece when bending, to achieve the product quality requirements, but the rubber pads, rubber sleeve, Urethane block and hard rubber is easy to deform in the bending process, the service life of a short period of time, affecting the dimensional accuracy of bending work pieces, is only suitable for dimensional accuracy does not require a high level of bending of the work piece.

In summary:

There are many types of bending machine press brake tools, each of which has its own specific scope of application. In the actual use of the process, according to the use of different materials, the size of the angle and the shape of the work piece, etc., carefully select the appropriate bending machine press brake tools.