CNC bending machine for a new type of large and medium-sized equipment, its high precision to obtain many people’s favor, you can choose a flexible method of actual operation, both the two machines can be linked to deal with too long metal plate laser processing problems, but also by a single version of the actual operation of the production and processing, reasonable enhancement of the utilization rate, cut down on energy consumption, the compensation of CNC machine tools by the fully automated adjustment, convenient.

The CNC bending machine includes a support frame, an operating platform and a clamping plate, and the operating platform is placed on the support frame, and the operating platform consists of a base and a pin: the electromagnetic coil is placed in a groove of the seat shell, and the top of the groove is covered with a rear cover plate.In the application, the electromagnetic coil is inserted by the transmission line, which will attract the pins, and then complete the clamping of the pins with the metal piece in the middle of the base. Due to the selection of magnetic clamping, the pin can be made into a variety of product workpieces, which can be produced and processed out of the outer wall of the product workpieces.

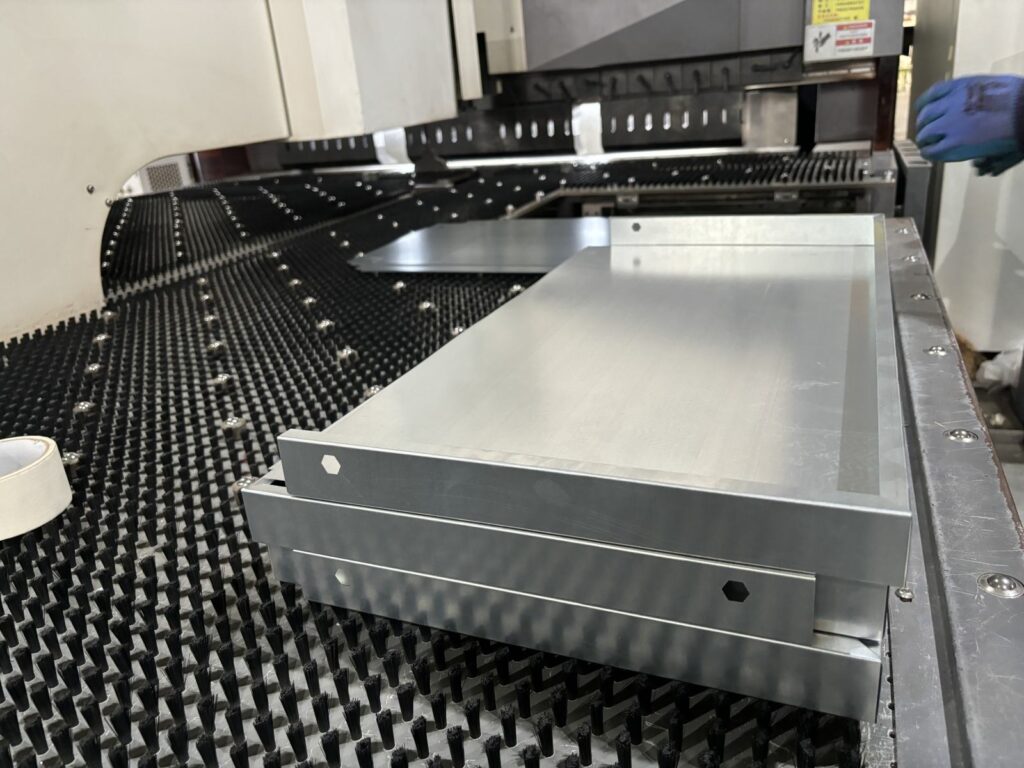

Machine Advantages

1.The whole body of the machine is machined, and the whole quenching and tempering treatment, with high strength and rigidity, can ensure the machining precision.

2.CNC molds are easy to use and lightweight, and can be assembled in different sizes according to the particular product.

3.The system is stable, simple to operate, and particularly user-friendly in design.

4.With angle programming, precise positioning of the rear gear, fast efficiency in one step, and ordinary bending machine compared to CNC bending machine processing speed faster and more accurate.

Practical operating procedures for getting started with CNC bending machines:

First of all, before operating the machine, we need to understand the components of the equipment, its overall structure is mainly divided into bracket, clamping plate and table three parts, each part is indispensable in the use of the process must ensure that all three have no problem in order to operate continuously.The principle of its use is mainly when the wire and coil energized will produce gravitational force on the platen, when the gravitational force can be realized between the platen and the base of the clamping, so as to achieve the bending of the sheet, the detailed operating procedures are as follows:

- Preparation for energization

To use the CNC bending machine is the first thing to do is to make the bending machine first power, we need to grasp the panel in the bending machine to open the power supply start switch, and then start the oil pump, if we hear the sound of the oil system rotation, then on behalf of the bending machine has no problem, at this time we do not need to do any work, so that the oil pump idling about 80s:

- Stroke adjustment test

The second link we need to test the machine for the work of the stroke adjustment, detailed operation is mainly for the upper mold downstream exactly the position of the Department of the need to retain a plate thickness, this step is to ensure that the bending machine can work properly does not affect the use of the bending machine cycle of the important links, must not be ignored;

- Select the groove

Bending thickness, notch size in this step to choose, based on the actual standard to set up the program, within industry standards, the size of the notch based on the thickness of the sheet to intend to choose the normal thickness of the sheet 8 times the width of the size of the socket, for example, the bending of the 3mm sheet, you need to choose the 24mm notch, the calculation is particularly concise.

- Adjusted stopper

This step is mainly to confirm the position of the backstop and the degree of specification to ensure that it can work properly;

- Step on the switch to work

The above preparation, testing work done after we can step on the switch to start the beginning of the plate bending, need to pay attention to is the bending machine pedal can be loosened at any time, loosening, stepping on the principle of stepping on the work of loosening and stopping, especially concise.

Importance of pre-startup inspection:

Pre-startup inspection is an important part of ensuring the normal operation of the equipment and preventing safety accidents. By checking whether the fasteners, buttons, handles, switches, knobs and other parts of the equipment are intact, it can ensure the stability and reliability of the equipment. At the same time, checking whether the safety guards are complete and effective can guarantee the safety of operators. Good lubrication can reduce the wear and tear of the equipment and prolong its service life. No-load running check can test whether the basic function of the equipment is normal, laying the foundation for the subsequent bending operation.

The Role of Programming and Simulation:

Programming is one of the core aspects of CNC bending machine, through which various complex bending operations can be realized. Simulation can check the correctness of the program before the actual operation to avoid problems in the actual operation. Through the simulation run, the operator can understand the running process of the program, and discover possible problems in advance and make modifications.

Significance of adjusting equipment parameters:

The setting of equipment parameters directly affects the quality and efficiency of the bending operation. According to the material, thickness and bending angle of the workpiece to adjust the bending pressure, speed, stroke and other parameters of the equipment can ensure the accuracy and stability of the bending operation. If the parameters are not set properly, it may lead to workpiece damage or equipment failure.

Precautions for placing workpieces:

When placing workpieces, it is necessary to ensure that the workpieces are fixed reliably to avoid displacement or tilting. For large or heavy workpieces, special fixtures or lifting equipment should be used for handling and fixing. At the same time, you need to pay attention to the position and direction of the workpiece to ensure that it meets the programming requirements.

Importance of starting equipment and monitoring operation:

After starting the equipment, you need to closely monitor the operating status of the equipment. By observing the equipment’s operating status indicator, listening to the sound of the equipment and observing the bending of the workpiece, etc., you can find the problems that may occur during the operation of the equipment in a timely manner. Once the abnormal situation is found, you need to immediately press the emergency stop button and take measures to deal with it.

The significance of inspecting the finished product and cleaning up the site:

After the equipment completes the bending operation, the quality of the finished product needs to be checked. By checking the size, shape and appearance of the finished product, you can determine whether it meets the requirements. If the finished product has quality problems, it needs to be reworked or scrapped. Cleaning up the equipment and the work site can maintain a neat working environment and improve work efficiency and safety.